The Woodworker’s Knife Guide

The woodworker’s knife has a thin steel blade attached to a handle, sometimes the steel blade is retractable or folds. These can also be known as scoring, striking, marking or layout knives. They generally come with plastic, metal or wooden handles.

Uses

The knife is used to cut through the surface fibres of the wood to create a ‘knifewall’ which helps create a defining line in layout and, when sawing, can help create a cleaner cut. A pencil line is often used to mark out where cuts should be made, but the pencil lead is rarely sharpened to a pin point, so the thickness of the nib allows for some variance when marking the lines. This may only be a tiny amount off, but this can really affect the finished project and the sturdiness of the joints. This is why pencil lines are treated as guidelines, not final cut lines. Once the pencil lines have been marked out, the accuracy of the angles can be checked with a square then marked over with a knife. Often two passes with the knife are used, the first cut should be very light which helps to ensure that the mark is accurate, the second pass is heavier and always follows the same path as the first. A knifewall often acts as a part way stop cut to avoid you splitting the wood further when using a chisel, it provides not only a visual barrier, but a small physical one too.

Terminology

- Knifewall – This is a term created by Paul to describe a cut through the surface fibres of the wood, and then using a chisel to create a stepdown so that other tools (chisels, saws, etc) can be used to precisely align them to the knifewall. Whereas it is common to use a pencil for initial layout, the knifewall allows for a more accurate marking.

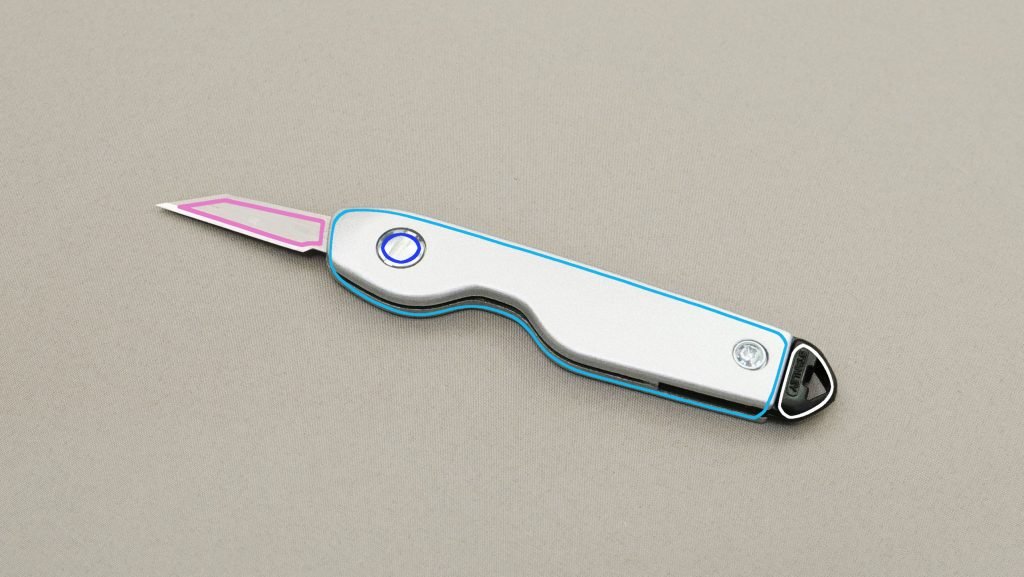

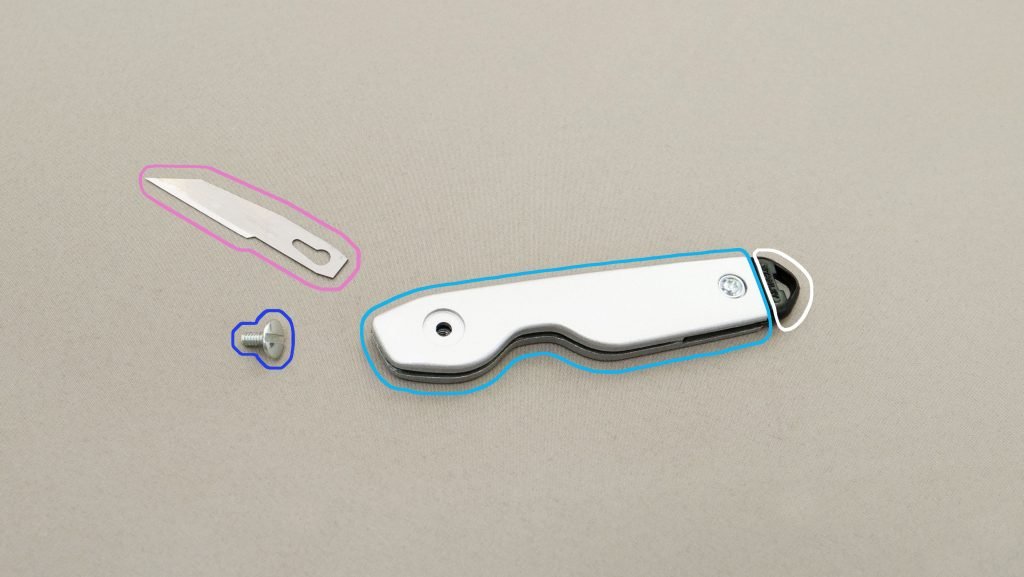

Parts of a Woodworker’s Knife

● Blade

● Access Screw

● Handle

● Lock

Relevant Guides

-

Setting Up and Sharpening a Woodworker’s Knife

Note: Be careful when sharpening as the tools will become very sharp, always face the blade away from you when sharpening. Often the knifepoint of the blade breaks off quite soon in use, this is because they are used more heavily for woodworking. As they do wear away more quickly than if they were used…

-

Using a Woodworker’s Knife

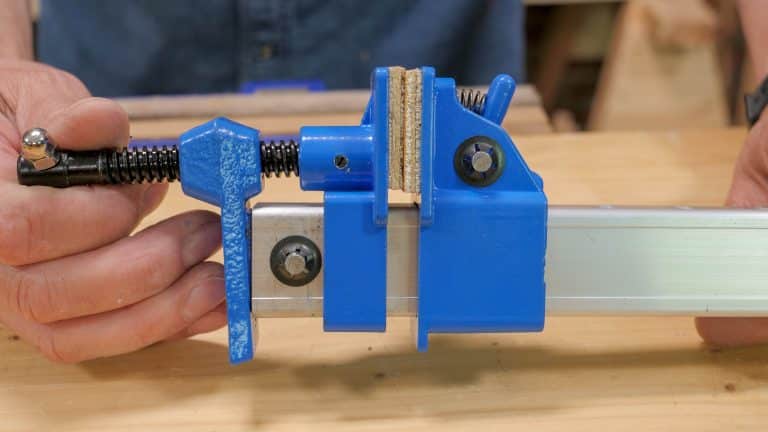

You hold the knife by gripping around the handle, rest your thumb on the side and use your index finger to apply pressure to the top of the handle, this will allow you to vary the pressure, and therefore the depth of the cut and maintain firm control of the knife. This is made easier…

Further Reading

To read more on this we recommend the following from Paul’s blog:

Do you sharpen the Stanley blade or just replace the blade?

If you do sharpen it, will you share specifics?

Hi David,

You can find out more about this in our Setting Up and Sharpening a Woodworker’s Knife guide.

Kind Regards,

Izzy