Sash Clamps

Sash clamps are used to hold together projects for an extended period of time, this is usually when gluing up to ensure the parts don’t move while the glue dries. They can also be used for temporary assembly (dry assembly) and to hold the components in the vise and on the bench top. As wood glue is water based, when applied the surface fibres of the wood swell, the clamps are there to stop any movement occurring. They can be tightened to create the desired amount of pressure and the length can also be adjusted.

Note: Paul recommends always putting your project together with a dry run first, this ensures that your parts fit together before you apply the glue.

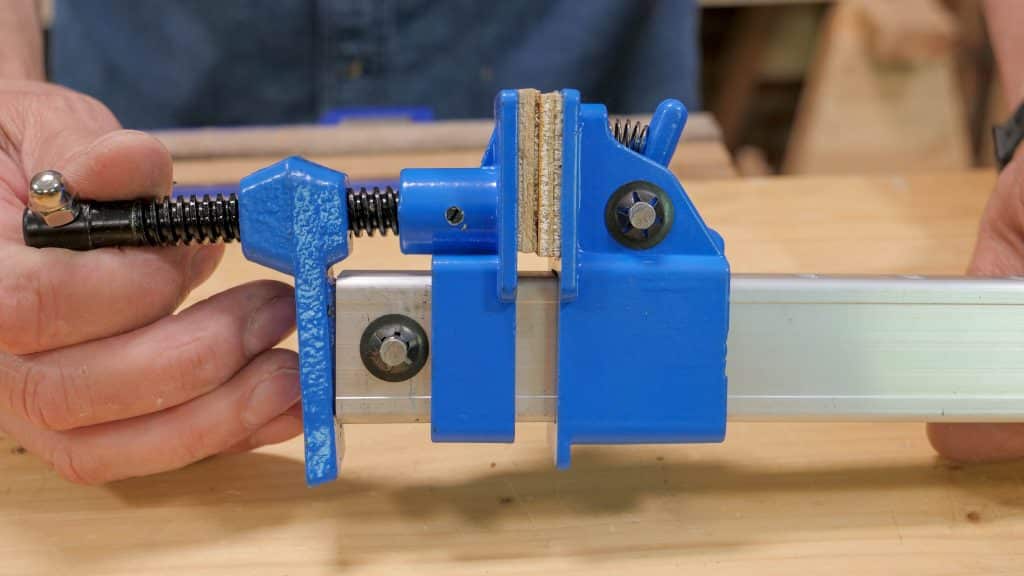

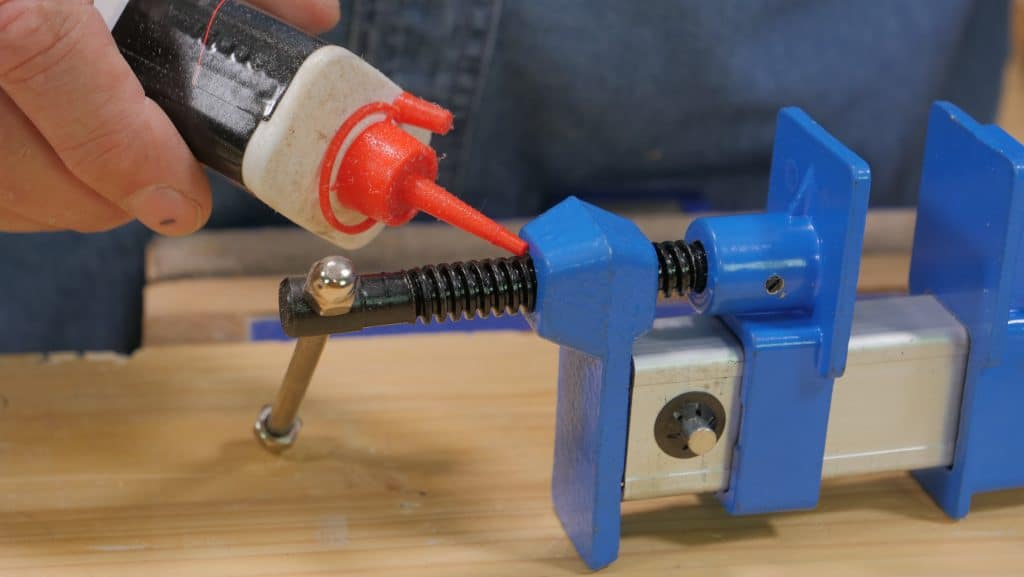

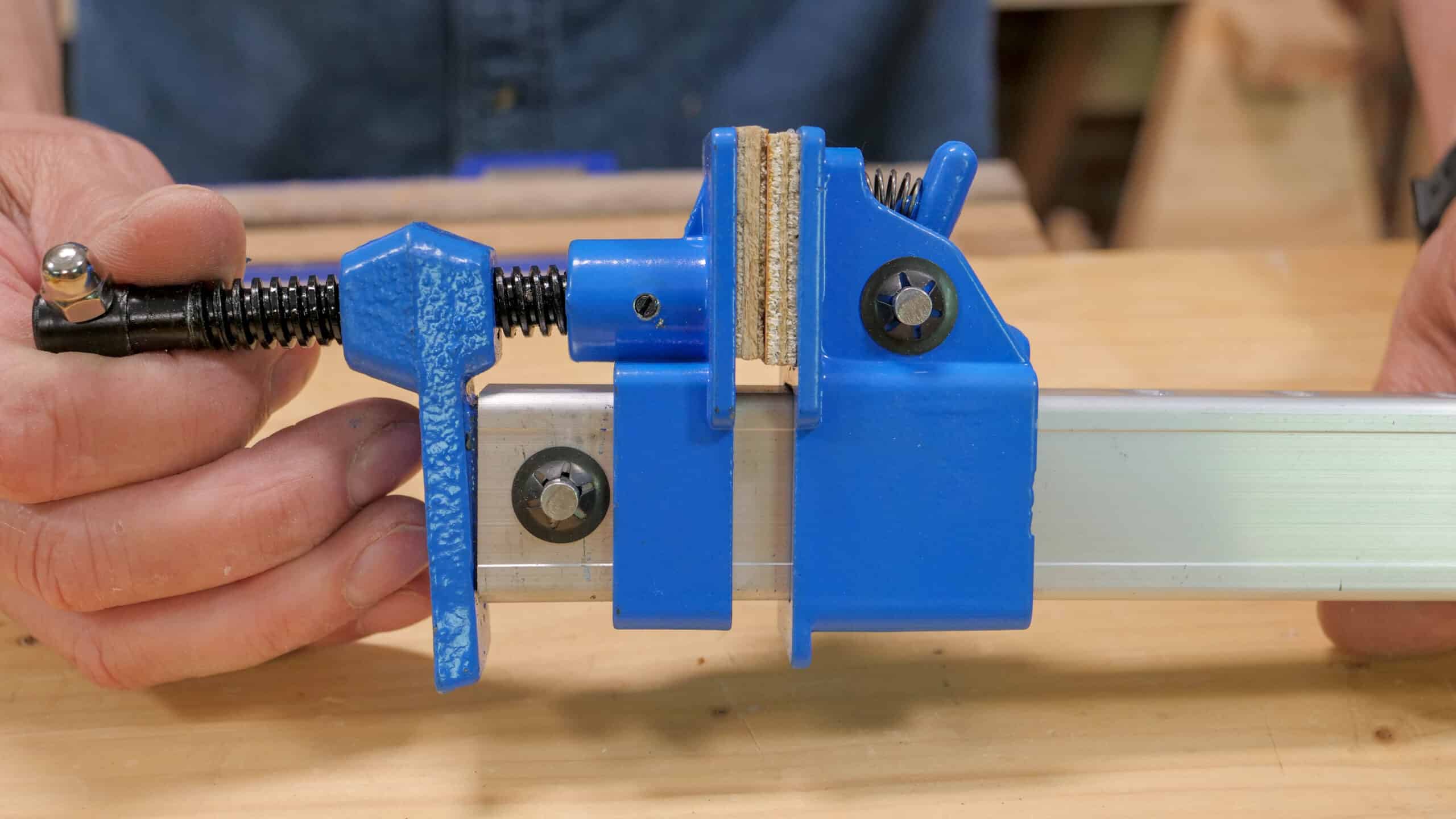

Setting Up

Oil the threads with 3 in 1 oil to stop them rusting and to keep the mechanism easy to adjust.

Add pads to the shoes, Paul recommends using plywood as this is sturdy and won’t mark the wood. You can fasten these using double sided tape or contact adhesive. If using contact adhesive, make sure to coat both the surfaces before, if only one is coated it will not stick. With double sided tape, press firmly then clamp the feet together to apply more pressure.

The lightweight aluminium clamps have a tendency to twist, you can add a piece of wood down the core of the beam to help reduce the amount that the clamp twists. You are after a snug fit so it does not require any fastening. When finding the internal measurements, make sure to measure from the indents as you don’t want your wooden beam to catch on these. Use a chisel hammer to ensure the beam goes down all the way, then secure it by denting the stem with a nail punch and hammer.

Buying

When buying a sash clamp, you want it to be lightweight and strong. You can add things such as pads and a rod down the core for strength (see ‘setting up’). Sash clamps are rarely used alone so it is wise to buy several of these. By having more than one, you can apply equal pressure to your project.

Paul recommends buying 2x 48” (122cm), 2x 36” (90cm) and 4x 24” (61cm).

🇬🇧 We purchased these Silverline Sash clamps from Amazon in May 2018:

600mm for £8.65. In our latest price check* the price was £14.99

900mm for £11.38. In our latest price check* the price was £17.99

1200mm for £12.29. In our latest price check* the price was £26.07

🇺🇸 Available on Amazon.com

*Prices checked March 2024

Further Reading

To read more on this we recommend the following from Paul’s blog:

In the US you can go to Harbor Freight and get similar clamps and do the same thing that Paul did to his.

Hi Paul and Crew,

I have found when using double stick tape (several different brands) the pad (both plywood and leather) will slide up with pressure applied. I have found this happening on different brands on sash clamp and assumed the “jaws” were out of parallel. Any suggestions how to keep the pads from sliding?

Hi,

I have passed on your query to Paul and below is his answer:

Yes, not all double sided tapes are created equal. I have been fortunate to have access to extra strong double sided tape. If you want to, you could use contact cement.

Kind Regards,

Izzy

I appreciate Paul introducing me to this kind of clamp, as I’ve really struggled using the regular bar clamps that seem to be sold everywhere. I recently purchased a set of ‘universal bar clamps’ from Dubuque Clamp Works (made in my home state of Iowa) which are the same style as the sash claps shown here, from Tools for Working Wood: https://www.toolsforworkingwood.com/store/dept/CDC/item/MS-ABAR.XX

I was introduced to them by a commenter at Paul’s blog.

They are very sturdy, with a much higher build quality than others on the market, featuring much thicker aluminum as compared to the claps shown, and very robust Acme threading. They cost a bit more than the overseas-produced clamps, but I’ve come to believe the quality trade off is worth it. A comparison of the build quality between these clamps and Dubuque’s: https://www.toolsforworkingwood.com/store/blog/1053/Clamp%20Vs.%20Clamp

I cleaned the clamping surfaces with rubbing alcohol and then applied plywood pads with a high quality double sided tape, so the hold in place just fine.

They are available from Lee Valley as well.

Can Paul recommend the Dubuque 36″ (USA) Aluminum Bar Clamp from Dubuque Clamp Company. They seem to be superior to what I have been able to find elsewhere and the price is very reasonable. Thanks

Hi Jasper,

Paul says:

They are very good clamps, excellent quality but tend to be a little more expensive. I like them very much because they, again, are lightweight and damage the wood much less than steel clamps.

Kind Regards,

Izzy

Izzy,

The Dubuque 48″ Aluminum Clamps are $28.50 from the Harry J. Epstein Co. at https://www.harryepstein.com/index.php/catalogsearch/result/?q=Dubuque+48%22+%28USA%29+Aluminum+Bar+Clamp

They also carry the 36″ and 24″ clamps. I hope my purchase was a wise one.

On some projects I see Paul use some really small sash clamps just wondering if he’s cut some down

Hi Antony,

Paul says:

I did, I cut some down as they are very handy.

Kind Regards,

Izzy

I have been using the Harbor Freight sash clamps for a few years. Only issue I had was twisting or bowing. Took Paul’s advice and they are as good as my buddy’s ones from Rockler at 25% the cost.

Silverline cramps VC63 I bought from Amazon UK appear to be the same as used by Paul. However, I bought some Iron Grip ones yesterday from a hardware store that looked the same, but when I got home I noticed that they had two rivets holding the head on, not one, and that nearly halves the head travel on the screw. Not sure how well they will work out.