Bench Plane Setup

Note: This exercise will get you familiar with the parts of the plane and where they go. To see the video on putting the plane together, click here.

You will need:

Start by dismantling the plane, take any removable pieces apart, including all the screws but not the tote threaded bolts, and lay them all out.

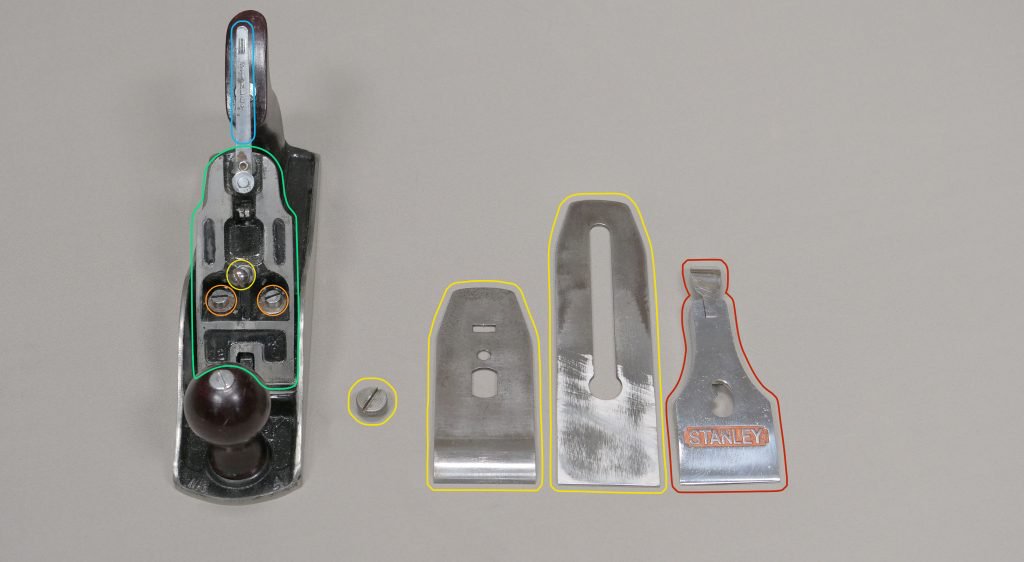

Test yourself to see if you can name each one and refer to the pictures below to see if you are correct.

The colour code is below the picture.

● Sole

● Handles (Front Knob and Back Tote)

● Cutting Iron Assembly (Cap Iron, Cutting Iron and Screw) and Setscrew

◎ Depth Adjustment Wheel

● Lever Cap

● Frog

● Lateral Adjustment Lever

● Frog Setscrews

● Frog Adjustment Screws

Put your plane back together in the order specified below:

- Put the front knob and the back tote onto the sole

- Put the frog adjustment screw back on the sole

- Place the frog into the inside of the sole and replace the two frog setscrews to secure it in place. Put the centre setscrew in place in the frog ready to hold the cutting iron assembly.

- Place the cap iron, cutting iron and setscrew together, this is known as the cutting iron assembly. Put the cap iron on top of the blade at 90 degrees then twist the cap iron back into place by swivelling them together; take care not to run the cap iron into the cutting edge as this could blunt or damage the cutting iron edge. This is also for safety as it means the actual cutting edge is never facing towards your opposing hand.

(To view pictures of how to assemble the cutting iron assembly, click here.)

- Screw on the depth adjustment wheel at the back of the frog, then place the cutting iron assembly onto the frog. Make sure it is lined up so that the protruding rectangle from the yoke slots into the cutting iron assembly and the circle on the lateral adjustment lever locates fully inside the long slit of the cutting iron.

- Make sure that the lever cap cam lever is in the open (upward, non-engage) position, place this on top of the cutting iron assembly and locate on the setscrew before pushing the lever on the lever cap down to secure it in place. You will need to adjust the setscrew incrementally to ensure the cap iron slots in and locks down without too much pressure. You want it to be secure but not too difficult to lock down or release.

By turning the setscrew, we affect the amount of pressure needed to set the lever.

Could you show a close up of the cap iron and cutting iron set up? How much of the blade should should extruding from the cap iron? Hope that makes sense.

Thanks!

Hi Ryan,

I have passed your question on to Paul and below is his answer:

1/32 – 1/16th and the plane iron will work well at any distance between those two.

Kind Regards,

Izzy

i have a question about the mouth opening. How much of an opening should there be in the mouth of the plane?

Hi,

Thank you for your question.

Paul says: The mouth opening can be changed by moving the frog on the plane which adjusts the cutting edge to the fore edge of the plane, a good distance is 2-3mm.

The following guide may help you: https://commonwoodworking.com/sharpening-a-plane/

Kind Regards,

Izzy

Hi,

I have a question on the cam lever, what position should it be when planing flat and does it need to be moved when planing on an angle?.

Hi Paul,

I asked your question to Paul and his answer is below:

The lever cam only secures the cutting iron assembly therefore to lock this in place is simply a question of folding the lever cam down all the way. You must adjust the set screw just below the lever cam while pressing the lever cam to get the correct pressure.

Kind Regards,

Izzy

The sides of my bench planes are rusting, can you recommend a good enamel paint or japanning or somesuch that can prevent the rust?

Hi Jeff,

Paul says:

I would use Boshield, this will prevent rusting and keep the plane looking good. I certainly would not paint the side of a plane.

Kind Regards,

Izzy

I have a number of planes from my ancestors 🙂 and flea markets, but many are missing parts (mostly cap iron screws or broken adjuster knobs [small low angle block plane.] I did enjoy your video on reconditioning and tuning planes, but I need more info and resources. Where would I find a supply of replacement parts and more info on planes and plane repair, particularly on the full variety of plane types? Thanks if you can help. (I am in the states.)

Hi John,

Paul says:

I found various parts on eBay are offered frequently, enough to build your own plane from if you needed to. I do believe that Stanley Sheffield UK still stock most parts for their planes if you want new parts.

Kind Regards,

Izzy

question about a #4 woden plane. the depth of cut adjuster on the frog, the small nub that goes into a hole in the blade, seems to be too short to catch onto the blade and move it, normal thin blade marked woden and woden chip breaker and cap, any solution for this ailment? it looks like when it is adjusted to push the blade in or out, as the tip swings along an arch, the angle it is at when engagement starts makes it to short to do much. thanks

Hi Colin,

Paul says:

Sometimes planes get cannibalised by dealers and you may not have a totally authentic plane as the plane may have been fitted out with anon-woden iron.

Izzy

When replacing the cutting iron assembly after sharpening, especially when reassembling for the first time after a restoration, does it matter whether your depth adjustment is (all the way) in or out? Is one or the other better for assessing whether your frog position is good?

Hi,

Paul says:

Not really, but better to split the distance before hand as we rarely have the blade adjustment extended to both extremes.

Izzy

I’m having an issue setting up a Bailey pattern jack plane. It is a Keen Kutter brand and it appears that the (almost definitely original- I’ve seen my dad take perfect shavings with it) cutting iron is thicker than most. I’ve sharpened a rounded bevel which I believe is recommended by Paul. However, it seems that the knuckle of the bevel hits on the rear opening of the mouth, and forces the cutting edge either into or too close to the front of the mouth to function. I’ve tried many, many different configurations of frog location and chipbreaker adjustment (that is, cutting iron protrusion distance) but keep coming back to this issue of the mouth. Would it be advised to grind a non-rounded bevel to flatten out this knuckle and make the presentation of the blade/chipbreaker a mm thinner or so at the mouth? Perhaps with a secondary bevel up at the cutting edge to get the correct angle? Or does it seem like I’m missing something entirely? Thanks!