How To Make a Rounded Card Scraper

This is known as a ‘curved’ or ‘round’ scraper and is mainly used for refining a bowl shape carved into wood.

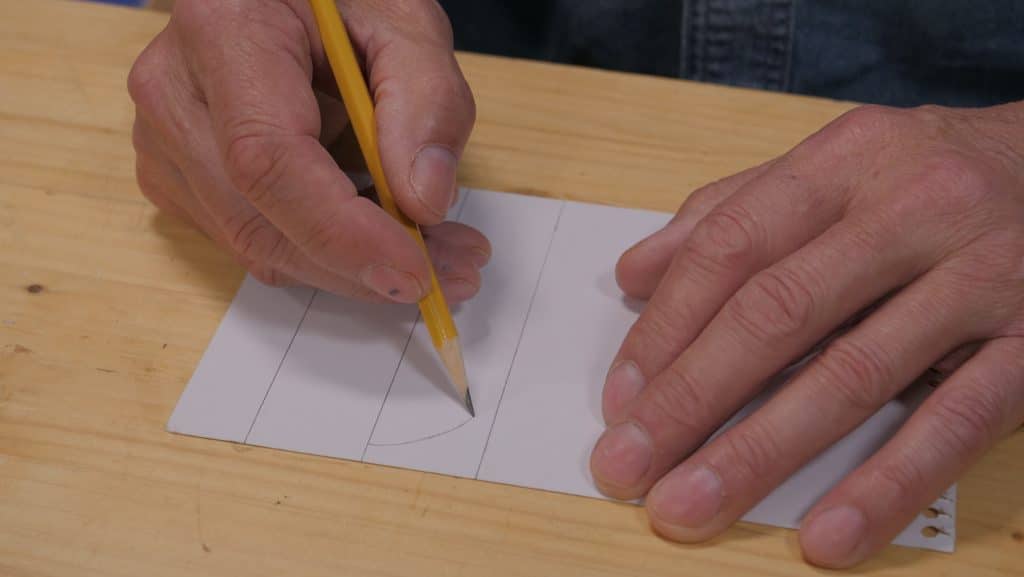

Draw the centre line down a piece of cardstock, draw a rounded, quadrant shape on one half and cut to shape.

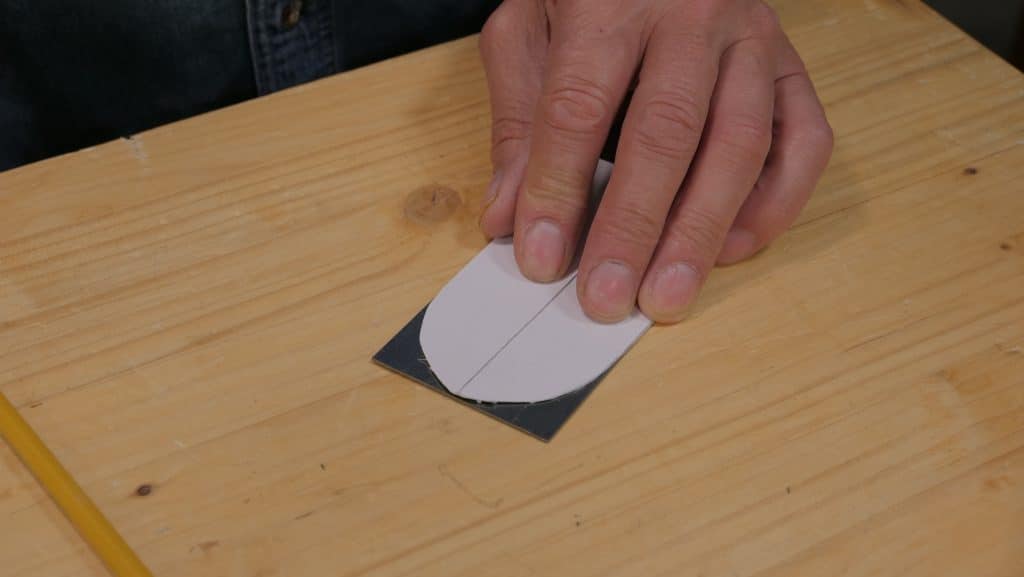

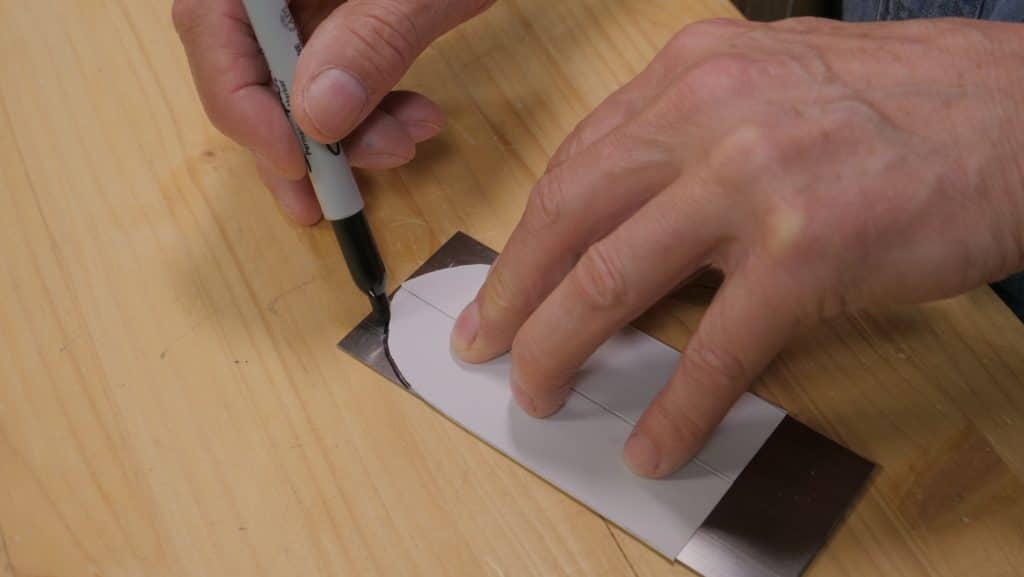

Fold down the centre line and follow the rounded edge using a knife or scissors.

Open it up to show the perfectly symmetrical curve, this can be transferred to the card scraper using a marker pen. You may need to make further adjustment to develop the rounded profile you want.

Clamp the scraper to a piece of scrap wood as a backing to stop movement and flexing, softer wood will work best, and use a hacksaw to cut the corners off. Once you have cut the majority of the way through, you should be able to remove the rest with a pair of pliers by bending the corner back and forth until it snaps off.

Note: Be careful when holding the steel as it will get hot during cutting due to the friction. If it gets too hot to hold, use a pair of pliers to hold it.

Use a file to shape this down to several flat faces before using a continuous stroke in an arcing motion to form the rounded edge.

Note: Be careful when taking the scraper out of the vise as the metal can get hot from the friction of filing.

Use the three different grit size on sharpening plates or abrasive paper to refine the edge. This process will create a burr that must then be removed. Remove the burr by placing each large face flat onto the finest sharpening plate and move back and forth.

The burnisher should be used as a final step to consolidate the steel on both faces by laying the scraper flat on the bench and using the burnisher over the edge back and forth. Next, put the scraper in the vise and follow the rounded edge with the burnisher. Start out square to the edge and the start to angle the burnisher incrementally with each stroke. This both consolidates the steel into itself and forms the cutting edge you need for scraper cuts.

Hi all,

Thank you so much for all the information you have provided. It is priceless in its content & very informative.

Something that I do use & I have not seen seen it in woodworking forums on YouTube, is the disposable retractable utility knife. The edge that breaks off to gain access to a sharp point makes for a good mini & safe scraper. If you feel this is an idea that is worth looking at & passing on please do :).

Hi Steve,

Thanks for the suggestion.

Paul prefers not to use a disposable knife and when he does he will have resharpened the blade.

Kind Regards,

Izzy

😄

I was so happy to see information on card scrapers here as I am looking to make one myself and I’ve never even seen one IRL. I have some questions about the burnisher stage as I’ve seen this term used for different types of tools for different types of projects.

Is the burnisher pictured a flat smooth piece of steel similar to a file?

Aproximatly what angle are we looking to achieve for the cutting edge?

Can we get a close up picture of the cutting edge showing the burr?

Thanks so much in advance and I look forward to looking through the site. Maybe I’ll even find my answers on another page.

✌️Devin

Hi Devin,

The burnisher is smooth steel which has no teeth, unlike the file. For the cutting edge, the angle can be anywhere between 7-15 degrees to develop an edge, the shallower angle will give you a less aggressive cut. Unfortunately the burr is too small for us to photograph.

Kind Regards,

Izzy

I bought the 4 scraper set from Veritas. Which scraper is best suited for the rounded spoon scraper?

Hi,

Thanks for your question.

Paul recommends either of the mid 2 sizes for a rounded card scraper.

Kind Regards,

Izzy

Hi All,

What could be some choices for easily available materials to make the scraper? Thank you, Patrick

Scrapers can’t get much cheaper and this is a good quality one.It’s a lot of work to cut the steel for a scraper from plate steel and finding the plate with the right steel qualities is even harder and certainly not worth the effort.