How to Make a Sharpening Stones Holder

In this guide, Paul shows you how to make a sharpening stones holder which can be clamped in the vise for ease of use.

For this, you will need:

- Plywood

- Holder: Paul uses 11 ½” (292mm) x 9 ½” (241mm) x ⅞” (22mm) but thicker or thinner works fine, but not less than ½” (13mm)

- Vise Block: 11 ½” (292mm) x ¾” (19mm) x ¾” (19mm)

- Steel Rule

- Pencil

- 3 x Diamond Sharpening Stones (To see which one, see our Diamond Stone Buying guide)

- Knife

- Gauge (or you can use a router plane for this)

- Chisel

- Router Plane

- Tenon Saw

Laying out the Recess Positions

Measure ¾” (19mm) in from each edge to create a border, put one of your diamonds stones on this border line and make sure it is spaced an equal distance from the top and bottom and draw around with a pencil.

Place the next stone ½“ (13mm) away from the first one and mark around. Repeat the same for the last stone.

Note: Use the stones themselves to lay out the recess positions as they can vary in size so using each stone to measure means that each recess will be tailored to fit that stone.

Go over the pencil marks with a knife and a square.

Chopping the Recesses

Use the chisel bevel down on the waste side of the knifewall, make chops along the length of the recess across the grain approximately 3/32” (2mm) with the chisel.

Use the router plane to reach the final depth of ⅛” (3mm). Paul recommends using a wooden router or one with a wooden sole if you have one, this is because the wood is less likely to mare the border of your holder.

If your diamond stones have feet, chop these off using a knife so they will sit flush in the recess.

Check the stones fit in their specific recesses, tweak if necessary.

Repeat on the other two stones until you are down to depth. Mark which recess fits which stone.

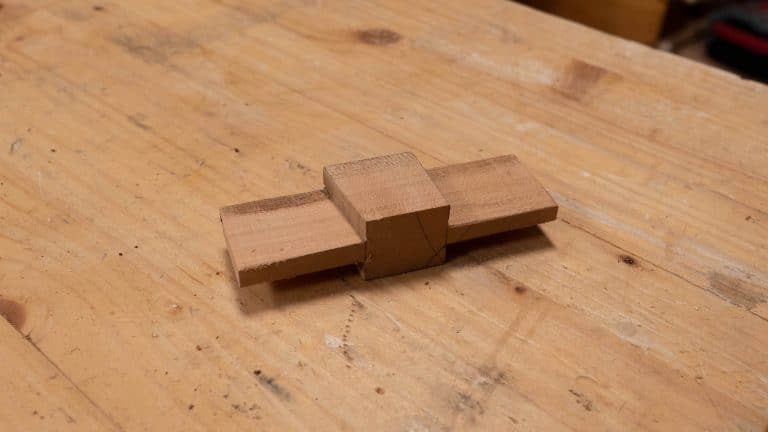

Cutting the Vise Block Recess

To attach the vise block to the underside you will be using a housing dado joint. Turn your holder upside down and mark ¾” (19mm) in from the edge using a knife.

Use the vise block strip of wood and line it up with the line you have just marked. Mark on the other side using a knife, tilt this slightly inwards to ensure it has a tight fit.

Set the gauge (or router plane) to 3mm and run this between both the lines on the edge. Use a ¾” (19mm) chisel to create a step down on the waste side of each line to guide the saw. Cut down both lines ⅛” (3mm), until you reach the gauge/router lines, using a tenon saw.

Use the router to reach the final ⅛” (3mm) depth. Check the recess fits the vise block, if it is too tight, plane down the vise block.

Glue the vise block in place. To ensure it is fully seated clamp it in the vise, this will remove any air pockets, this may cause some of the glue to squeeze out, wipe away with a tissue. Clamp overnight.

Finishing

Use 240 grit sandpaper all over the holder.

Finish the holder with 3 coats of varnish, including in the recesses, to avoid the holder absorbing the auto glass cleaner during use. Varnish is more durable than the shellac finish that Paul usually uses to finish projects with. However, it is applied in a very similar way so, see our ‘How to Apply Shellac’ guide for tips on this.

Fixing the Stones in Place

Once the finish is dry, use silicone to fix the stones in place in the recesses, this will enable you to remove them if you need to.

Note: Over time you may notice a build up around the edge of each diamond stone within the holder, this will be swarf residue. To remove, just use a chisel bevel down, be sure not to touch the diamond stone and this may damage the edge of your chisel.

Using the Holder

To learn how to sharpen your tools, see our Sharpening a Chisel guide.

Thank you Mr. Paul

Wonderful work and well done

Thanks Paul for a simple method to make the sharpening stone holder. I await my Router Chisel to finish the build, meanwhile I am using a chisel.

Forgive me, but wouldn’t it be easier to ADD strips of timber around the perimeter rather then removing the centre. Just as strong with 10x less work

Hi Rob,

Paul says:

But not necessarily the best way, less fiddly bits and more solid and we enjoy the challenge of good woodwork.

Kind Regards,

Izzy

Would poly work too? Just trying to think of the half cans I already have. Thanks can’t wait to make this.

Hi Brian,

Yes, nothing wrong with using this.

Kind Regards,

Izzy

Hey Team,

Since, we do not really have access to whetstones or honing guides and such nice equipment here in Egypt, would it be fine if i use Sandpaper with the grits Paul describes?

Many Thanks,

Fouad

Hi Fouad,

Paul only recommends using sandpaper as a short term solution as it can be costly. I have linked our guide below where he shows how to a sharpen a chisel using sandpaper: https://commonwoodworking.com/sharpening-a-chisel/#abrasive-paper

Kind Regards,

Izzy

Thank you so much Izzy, Paul’s instructive videos have changed my mind from trying to get power tools and finishing projects in an hour. Now thanks to him, i am taking my time with projects, trying to utilize more hand tools and this has helped enjoy this hobby way more. I just wish Egypt had access to some of the tools paul uses. But in the End thanks to Paul and you all, you are helping me a lad from Egypt enjoy woodworking as a hobby.

Many Thanks and Love,

Fouad Said

Hello,

I have a large-sized Kell honing guide, with rollers the span of which are wider than the 8” x 3” sharpening plates. To date I have used a jig I made to compensate for this. Would there be any problems with deepening the recesses of the holder to make the surfaces of the sharpening plates flush with the surrounding surface?

With thanks and kind regards,

Steve

Hi Steve,

Paul says:

No problem that I can see.

Izzy