How to Choose a Wood Finish

Note: This guide was updated on the 26th February 2019 to include more specific examples.

Before finishing, sand your project or section with 240 grit sandpaper, this gives the surface texture (also known as ‘tooth’) and gives the finish something to cling to. If your wood is oily, (like teak or rosewood) often we would wipe the surface with a solvent, such as denatured alcohol, to remove surface oil and improve adhesion by the finish, beyond that most finishes will work just fine on woods with oily content. Some woods, especially tropical hardwoods have high oil content. Most Western European and North American hardwoods are non oily wood.

Many if not most wood finishes manufactured today are non toxic once cured, but during the curing period can remain toxic if toxic ingredients were used in the manufacture. It is best to check with the data sheets all companies must provide if you are finishing projects such as food utensils, children’s equipment, furniture and toys.

Shellac

Shellac is easy to apply, and can be bought pre-mixed. It is a protective finish which is applied by brush or with a cotton pad made from a rag, t-shirt material works best. This finish is best for indoor projects. Blonde shellac is clear, you can dye it with leather dye, you can apply up to 4 coats, leaving half an hour to an hour between coats. You know you need another coat when you look at the surface and see dull patches, you want an even shine overall.

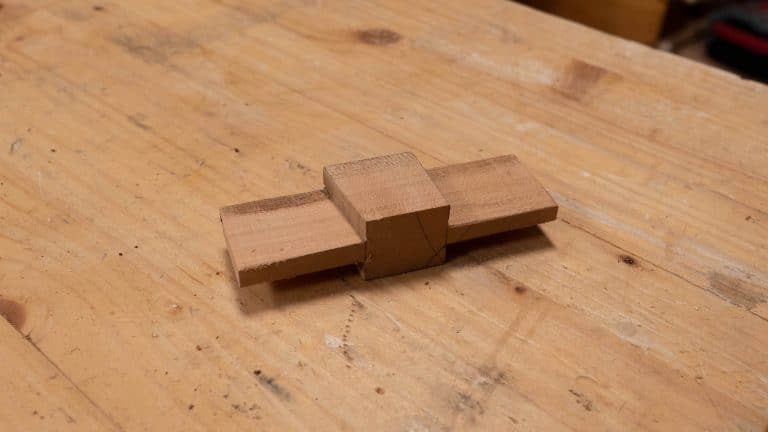

Pictured below is sanding sealer made from shellac.

Furniture Wax

This can be applied on its own or on top of shellac for a frictionless finish. If applied on its own, this will need to be topped up periodically, depending on how exposed the furniture is and how often it is used. Furniture wax can be clear or coloured, the wax fills the pores in the wood and is best for indoor projects. Furniture wax is not a very resilient finish but it does enhance the wood.

Varnish

Varnish can be coloured or clear. It is best for projects which come into contact with water. You can get specialised varnish for outdoor use which protects your projects against the elements. Polyurethane and varnish work identically as far as application and protection goes. Manufacturers offer different advice but many finishes do break down with ultra violet (UV) light and often finishes have inhibitors to increase longevity. The way that finishes are labelled and marketed there appears to be no difference between varnish and polyurethane, polyurethane is a varnish and both are oil based, however we now have water based varnishes which can confuse the issue of categorisation.

Varnish or polyurethane would work well to bring out the grain. Oil based varnishes dry as a clearer finish than water based varnishes so you get greater depth.

Oils

All true oils soak into the surface of wood grain, but some have polyurethane which forms a skin on the wood surface. Danish oil is one of the easiest finishes to apply which makes it easy to repair.

For food safe products, use a clean rag with a plant based oil, such as vegetable oil, leave to absorb and re-apply when desired over time. Mineral oil is also a popular choice for this category of projects.

Generally boiled linseed oil is an acceptable finish for garden and outdoor wooden tool handles, however it is not a durable outdoor finish.

Application techniques:

- Various finishes can be applied by hand using a cloth and are often referred to as hand rubbed. Use a rag to apply the oil then remove any excess with a cloth and wait for it to dry before the next application.

- French polishing is a highly specialised technique generally used on very fine and antique furniture. Shellac is the only product used for the process of french polishing.

- Brushes can be used to apply most finishes as long as you use a good quality one which doesn’t have loose bristles. Paul uses various brushes including a hake brush as the preferred method of applying shellac.

- HVLP sprayers are used as an alternative to brushing and rubbing as an application method. This works well to create consistently high gloss finish on projects like guitars and furniture.

- Steel wool is used between multiple coats of finish to buff out nibbing. Nibbing is often caused by contamination in the finish, particles of dust or air bubbles from the wood escaping into the surface.

- Cloth can be used as an alternative to a brush for some finishes and will result in a streak-free finish.

As manufacturers offer different advice according to their product, it’s recommended that you also follow their guidelines.

Further Reading

To read more on this we recommend the following from Paul’s blog:

I have been waiting for this post as I am about to finish one of my small projects. However, I’d really appreciate it if there was more depth to the article. For example, what about lacquer? Difference between varnish and polyurethane? When would I use one over the other? For instance, if I am interested in bringing out the natural grain of hardwood, which finish would do that best? Durability? How does each finish interact with oily woods like teak? All these questions would help me a lot in picking the best finish for my next project.

Hi Waldo,

As the choice of finish is dependent on many different factors, this guide only gives an outline of a few common ones.

Paul says there is no difference between varnish and polyurethane because polyurethane is a varnish and both are oil based, however we now have water based varnishes which can confuse the issue of categorisation.

Varnish or polyurethane would work well to bring out the grain. They do dry as a clearer finish than water based varnishes so you get greater depth.

Often we would wipe the surface with a solvent to remove surface oil and improve adhesion by the finish, beyond that most finishes will work just fine on woods with oily content.

I hope this helps!

Kind Regards,

Izzy

Thanks this was most helpful.

Are TungOil, Teak Oil or how about Boiled Linseed oil a great protectant for outdoor furnishings and wooden garden handles? Just wondered if someone could give me an idea of which finish is most durable and long lasting? Thank You

Hi Kathy,

I passed your question on to Paul and below is his answer:

Generally boiled linseed oil is an acceptable finish for outdoor tool handles, if you’re talking about gate handles then I would use another finish such as varnish. Tung oil and teak oil are manufactured to different standards and are therefore inconsistent which makes it difficult to advise on these.

Kind Regards,

Izzy

I also found the article a bit light. What should I use if I want a clear non wet look finish, something that leaves the wood in a natural state. Varnish tens to be wet look and wax colours, any recommendations?

Hi David,

Waterborne finishes in a semi gloss or satin will have a clear look and will not give you a wet look finish.

Kind Regards,

Izzy

Regarding food safe items, it has been mentioned to me that plant based oils are known to turn rancid from time to time, and that a food-grade mineral oil is the better choice.

Hi Sverre,

Thank you for your comment.

Paul says that they could go that route, he thinks the business of plant based oils turning rancid is most unusual and he’s never had that happen in 50 years of making cutting boards.

Kind Regards,

Izzy

Hi Izzy ….thank you

I agree with Waldo regarding “depth” …..but how far can you go? finishing requires years of experience starting with good basic instruction, not ( and I do not wish to be unkind to you) a few lines.

Take just one…..French polishing, you say “to be used on fine or antique furniture” Surely we are being taught how to make, yes small items, but fine finished articles…..these could be French polished couldn’t they?

I am in the process of making a small planter from mahogany and oak ( out of wood scraps ) this will be a gift for a neighbour from her husbands bag of wood offcuts.

Would you be able to advise an exterior finish suitable for both woods, in an attempt to retain woods colour.

Wishing you well John

Hi,

I passed your question onto Paul and below is his answer:

‘Finishing does not require years of experience, but specific crafts like French Polishing do take consistent practice over a number of months. All of the other finishes are applied either by brush, rag or pad and most people for instance, can apply a water based finish successfully without having much, if any, previously experience. I think the key issue is knowing which finish to apply for what and this is a matter of choice. French polish for instance on small items is high demand crafting whereas you can brush on the same shellac and end up with a resilient finish that looks great. Other finishes like danish oil require no skill at all.

Outside there really are only a couple of finishes, one would be outdoor varnish and the other would be something like Osmo oil which is a product intended for outdoor furniture.’

Kind Regards,

Izzy

Hi Izzy, I often come upon old furniture that needs a little sprucing up to give it new life. I recently bought shellac flakes because I wanted to have a finish that I could mix up myself, always be fresh and not be concerned about how long it’s been sitting on the shelf. I have two projects that need their surfaces protected but I don’t want to strip off the old finish. One is a child’s stool painted with a fairy tale graphic. The other is a glider rocking chair base runner that is either varnished or polyurethaned. Can I shellac over the painted stool if I clean it first with soap and water? How about the rocking chair base if I first scuff up the surface with steel wool? Any suggestions would be appreciated.

Hi John,

Paul says:

Shellac will cover any previous finish so you’re perfectly safe with shellac.

Kind Regards,

Izzy

Hi, it says in the text that polyurethane is oil based, but the Sadolin polyurethane varnish which is on the picture is actually water based according to the manufacturer. Could you recommend any oil based varnish instead? Thanks.

Hi Nikola,

Paul doesn’t have a particular preference or recommendation for an oil-based varnish.

Sorry we couldn’t be of more help.

Kind Regards,

Izzy

Hello, I’m building a Cornhole game set and am trying to decide on a finish to put on it. I am using Walnut and Hard Maple. I need something that protects the wood (it will be outside) and is very slick, so that the bean bags slide easily.

Would an oil based or water based varnish be good? Or something else? Thanks!

Hi Aaron,

I passed your question on to Paul and his answer is below:

There is no real waterproof outdoor finish, but I think you could use a yacht varnish as that seems to be the preferred finish for boat decks. I don’t believe the water based finishes will last as well.

Kind Regards,

Izzy

Hi Paul,

Great website full of information, which is helping me get through this difficult time. I have just have a quick question about ply. What finish would you recommend for 19mm plywood? I’ve just made a tv unit out of offcuts in my shed, it’ll go in my lounge so will be inside.

Also I was wondering what scrub plane you would recommend to true stock? If you would recommend a scrub plane or a no. 5 or something?

Thanks in advance, again keep up the good work 👍

Nige

Hi Nigel,

Paul says:

You could use either the water based wood finish or clear shellac.

I recommend that you convert a no4 plane to a scrub plane and I give details on this here:

https://woodworkingmasterclasses.com/videos/scrub-plane/

https://woodworkingmasterclasses.com/videos/using-scrub-plane/

Kind Regards,

Izzy

Hi,

Do you have a guide anywhere that explains what a “cut” of shellac means, e.g. 1lb, 2lb, etc?

I make my own shellac from flakes, and have no idea what “cut” I should be aiming for, and what quantities of flakes to meths that represents.

Thanks!

Darren.

Hi Darren,

Thanks for your question, I passed this on to Paul and he says:

I don’t have a formula for this, I just sense the amount I need after all these years so unfortunately I am unable to help. You can research online as there is a lot of information out there.

Kind Regards,

Izzy

Hi,

No worries, thanks for asking.

I post this in case anyone is interested in the future:

https://www.shellac.net/PoundCutChart.html

Cheers

Darren.

Hi,

I’ve made a mistake by applying the wrong schellac (wrong reddish dye) while i was willing to put a more darker one.

Is there a nice suggestion to remove it? I was trying with alchool and a rag and a lot of it is removed but not all, expecially on the end grain.

Thanks a lot

Giacomo

John, Paul’s apprentice gave this answer to your question:

Hi Giagomo,

End grain is the most absorbent section of wood, and some wood species have larger pores, therefore your best bet is to give it a good sand before applying a darker shellac.

Hi. Can Paul recommend a brush (make and model) for applying polyurethane varnish?

Thanks

Simon

A little more surfing through the site and I came across this:

https://commonwoodworking.com/consumables-guide/

Paul’s recommendation for a varnish brush under Consumables. Maybe this and the hake brush needs lifting up and repeating in Tools section ?

In the link i’ve inserted above Paul recommends the Corona Professional Ox-Ear Superfine – which is great to have the recommendation – but it’s not the one in the photo above. I’m curious to know what is the make and model in the photo above?

Sorry….keep answering my own questions here. The brush above is a 2″ Hamilton Perfection Pure Bristle Brush. Probably not as good as the Corona.

https://www.amazon.co.uk/Hamilton-Perfection-Bristle-Paint-Brush/dp/B001DKX8KU/ref=sr_1_2?keywords=hamilton+perfection+brushes&qid=1648971592&sr=8-2