The Plough Plane Guide

The plough (plow USA) plane creates channel grooves by removing material from the middle of a piece of wood, leaving two outside edges. The plane has a guide or fence, which runs along the underside or outer edge of the plane body to keep the groove parallel and the plane fully aligned to the material. This fence can be adjusted to change the distance of the groove in relation to the edge of the board.

Uses

The plough plane is used to create grooves parallel to an edge, this is useful in creating projects such as window sashes, frames for door construction, tongue and groove floorboards etc. Grooves are used in drawer construction as well as a wide variety of other frame and panel construction projects. The plough plane can be used to reliably create uniform grooves in different widths of cut.

Terminology

- Cutting Irons – High grade carbon steel cutting blades, they come in different width sizes, often in both metric and imperial measurements

- Fence – This is a metal or wooden guide that runs along the long axis of the main body of the plough plane and ensures that the groove is a consistent distance from the edge

- Depth Stop – This is a guide stop that prevents the plough plane from cutting beyond a predetermined level, ensuring a consistent depth to the groove

- Stems – Can come in multiple sizes, the bars which join the two parts of the plane

- Lever Cap – Holds the blade in place by pushing the knurled lever cap screw on the top of the blade

Types of Plough Plane

- Wooden

- Metal

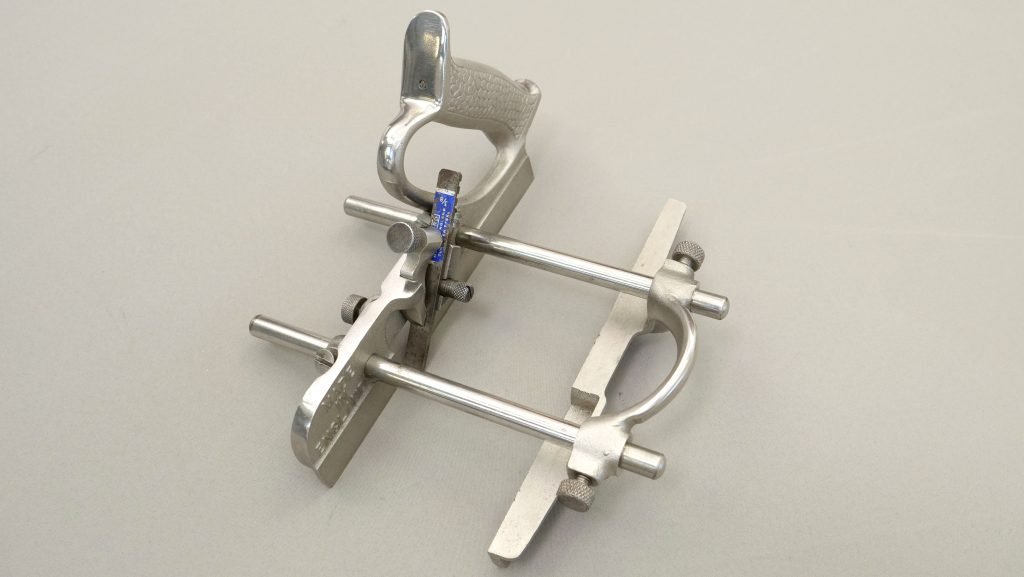

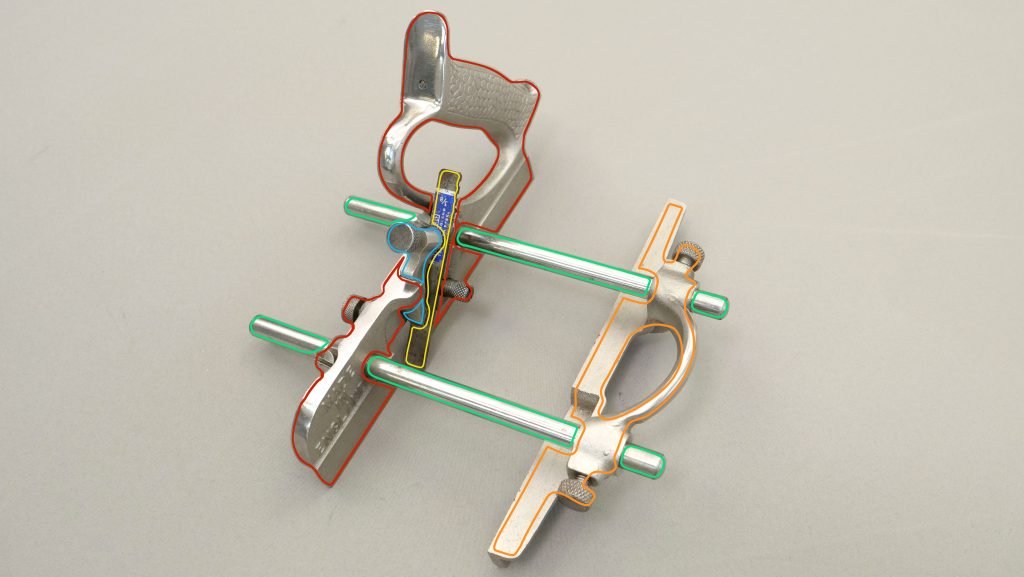

Parts of a Plough Plane

● Stems

● Body

● Blade Retainer

● Fence

● Blade

Relevant Guides

-

Sharpening a Plough Plane

Setting Up When buying second hand, the plough plane may be sticky with grease or rusty, this can be cleaned using a wire brush and abrasive paper. Your plough plane may also arrive in multiple parts, start by lubricating the stems with oil to ensure they go into the fence and body easily. Sometimes the…

-

Using a Plough Plane

When using a plough plane, the cutting iron can be set deeper than a smoothing plane as it is narrower and therefore requires much less effort to push into the wood. The cutting iron sometimes go under the wood’s surface fibres and causes them to tear because the side walls at the surface level are…

-

The Plough Plane Guide

The plough (plow USA) plane creates channel grooves by removing material from the middle of a piece of wood, leaving two outside edges. The plane has a guide or fence, which runs along the underside or outer edge of the plane body to keep the groove parallel and the plane fully aligned to the material….

Very informative to people who do not have the opportunity to learn under a trainer and are trying to learn from such helpful sources.

Hi Vineeth,

Thanks for your kind comment.

We are so pleased to hear you are finding the guides useful!

Kind Regards,

Izzy

I recently purchased a used Record 405 with nearly every part except for the many optional cutting irons that were once included with the new model. There really is quite a learning curve figuring out how each part works with the next and so on. I’ve only really found a use for it one time and wasn’t in the least bit disappointed in its performance although I might say my own performance may leave something to be desired. I also own a cheap Chinese knock off wooden plow plane that was absolutely garbage when I first opened the box, but several months of gently tweaking parts and sharpening the irons has it working probably as good as if not better than the complete Record. When the Chinese model first arrived it was coated with some kind of finish that took me weeks to sand off and the irons weren’t anywhere near ready for use and so I was fully prepared to toss it in the garbage, but perseverance and my innate distaste for throwing money away paid off. Point being I suppose is that just because something isn’t perfect out of the box is no reason to give up. Many tools are sold this way, in need of honing, cleaning and so forth before use. Sometimes it seems like it’s more work than it’s worth, but after getting my $30 cheap Chinese plow plane working well I’m not sure just how valid it is to say all cheap tools are junk.

The terminology is not clear to me. As I understand it, a groove and a dado are different. A groove goes with the grain, and a dado is cross-grain. Is a plough plane for cutting dadoes? Seems like you would have tearout.

John, Paul’s apprentice gave this answer to your question:

Even though some planes were marketed for cutting dados they don’t. To cut a dado read out guide which is found below:

https://commonwoodworking.com/courses/how-to-make-a-housing-dado/