Using a Honing Guide

Paul doesn’t consider these an essential tool, however he understands that some beginners may not feel comfortable starting with freehand sharpening. The honing guide is useful if you want to achieve an exact angle, however there is a bit of leeway when sharpening as chisels can be sharpened anywhere between 25-35° and plane blades can be sharpened anywhere between 25-30°.

Often honing guides have distances etched into the body which helps you position the blade and tells you how far this needs to be protruding to achieve the correct angle.

Place the blade into the honing guide, use the adjuster on the side to make the opening larger or smaller depending on the tool you are sharpening. Use the measurements on the side as a guide to tell you how far the blade needs to be protruding, use a steel rule to measure against. In this case Paul positions it at 40mm to create a 25° bevel.

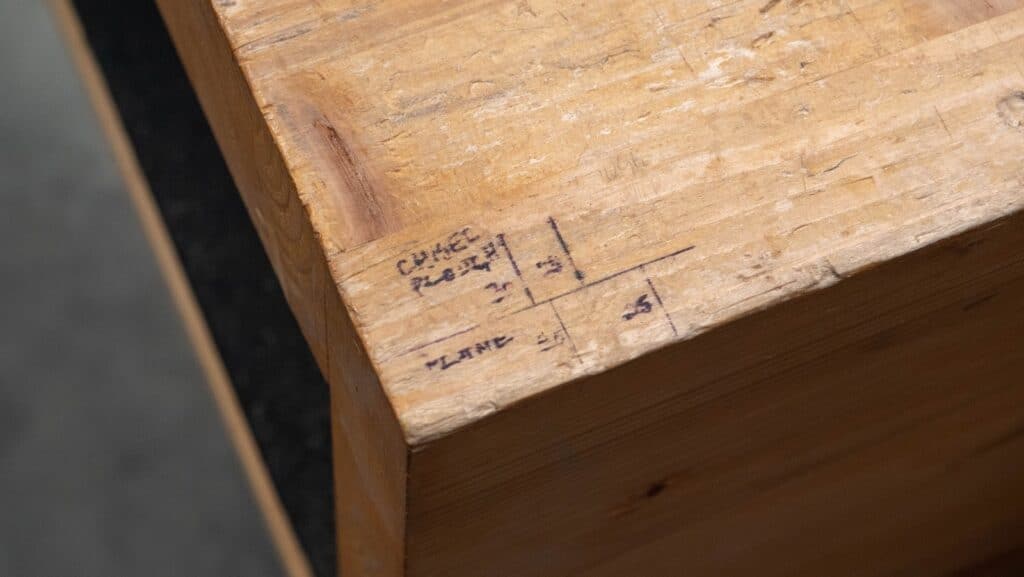

Tip: Paul marks these measurements on the edge of his bench to save time.

To establish the primary bevel, place the bevel against the most coarse surface you are sharpening on (Paul uses diamond stones) and use the wheels on the bottom to role this across the surface back and forth. Use your fingers to apply pressure to the top side of the chisel blade and push and pull it along the surface approximately 10 times.

Once the bevel has been established, change the position of the blade in the honing guide (use the measurements it recommends on the body of the honing guide) this will help you refine the cutting edge. This angle must be steeper than the primary bevel, in this case Paul changes the position to 30mm which creates a 30° angle. Repeat the same process as above with the blade in this new position but only on the superfine abrasive surface.

Tip: If you find the honing guide is stiff or squeaky when it rolls, use a little oil on the thread

Thank You Paul Sellers and Common Woodworking Team for all of the fantastic lessons!

I am surprised that Paul is suggesting a micro bevel. I thought that he felt that the micro bevel dulled too quickly. Did I remember wrong, or has this changed?

I thought the same thing.

Hi Philip,

Paul is not suggesting a micro bevel, he is suggesting a second bevel known as a secondary bevel. A micro bevel is barely the width of a strand of cotton wide, whereas a secondary bevel might be up to 1/16” wide and this is necessary step when using honing guide.

Kind Regards,

Izzy

Thanks for the clarification Izzy.

So when Paul is Free Hand sharpening he doesn’t do the secondary bevel because the motion he uses rolls slightly and creates a camber that works similarly? Is that accurate?

Thanks,

Collin

Hi Collin,

Paul says: Yes, but the reason I prefer the camber is in my view, it’s a much stronger, more resilient bevel.

Kind Regards,

Izzy

Phillip, Rick, Collin:

Where do you find Paul’s comments/instruction on chisel camber, micro bevel strength etc. – can you give links? The videos are wonderful but it’s a bit like a forest where I can’t find individual trees.

Hi Alexander,

You can find more information in the ‘Sharpening a Chisel‘ guide.

Kind Regards,

Izzy

Hi Izzy,

I use a honing guide same as you pictured for chisels bevel setting, however I found it sharpen out of square, especially the chisel position. Have you find the same and is there a way to overcome this?

I find filing the guide back to square difficult, because each chisel will sit differently in the guide (especially firmer vs beveled chisels).

Best,

Benoît

Hi Benoît,

I passed on your question to Paul and he said:

I haven’t had an issue, but the guide itself does not in any way guarantee squareness at the cutting edge as you can still press the guide slightly more on one side than the other.

Kind Regards,

Izzy

Can you confirm the make of honing guide that Paul uses?

Hi John,

Paul freehand sharpens but recommends the Eclipse honing guide for beginners, you can find out more about this here: https://commonwoodworking.com/sharpening-tools-and-accessories/

Kind Regards,

Izzy