The Combination Gauge Guide

…Gauges Part I- Old and New Marking Gauges Part II- Mortise Gauges and More Mortise Gauges to Look For Another Point of Mortise Gauges Buying Good Tools Cheap- Marking Gauges…

…Gauges Part I- Old and New Marking Gauges Part II- Mortise Gauges and More Mortise Gauges to Look For Another Point of Mortise Gauges Buying Good Tools Cheap- Marking Gauges…

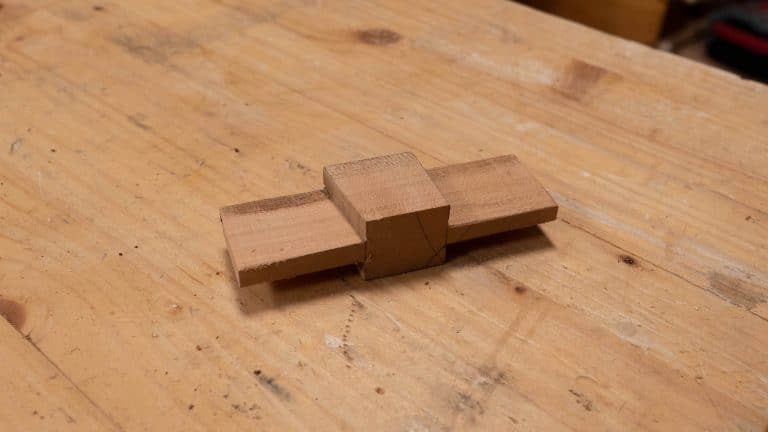

Buying a combination gauge is more cost effective as it essentially combines the marking and mortise gauge into one gauge. Paul recommends the type that have pins rather than discs…

…Gauges Part I- Old and New Marking Gauges- Part II- Mortise Gauges and More Mortise Gauges to Look For Another Point of Mortise Gauges Buying Good Tools Cheap- Marking Gauges…

…Gauges Part I- Old and New Marking Gauges- Part II- Mortise Gauges and More Mortise Gauges to Look For Another Point of Mortise Gauges Buying Good Tools Cheap- Marking Gauges…

Take a mortice gauge (or combination gauge) and set the pins to the exact width of the ½” chisel (12mm) you will be using later to chop your mortise hole….

…used in pairs and sometimes with three, very rarely do we use one hinge alone. Equipment needed: Hinge and screws Screwdriver Gauge Chisel Square awl Knife Chisel Hammer Square Place…

…Set a gauge to the thickness you want the finished material to be planed to. Register the stock of the gauge against the face mark side and push the gauge…

…your mortise gauge to the exact width of your 1/2″ chisel Run your gauge between the pencil lines Ensure you stay well registered against the front edge For the exact…

…can use a gauge. Set the gauge to the thickness of the cheek, we suggest about ¼” (5mm) deep, and run this down each face and along the end grain…

…May 2018 Buying a combination gauge is more cost effective as it essentially combines the marking and mortise gauge into one gauge. Paul recommends the type that have pins rather…