Setting Up and Sharpening a Spokeshave

Note: Be careful when sharpening as the tools will become very sharp, always face the blade away from you when sharpening.

Setting Up

If your spokeshave is secondhand, check the angle of the bevelled edge using a protractor. The bevel should be no more than 30°.

To set the cutting iron depth, use the two adjusters one at a time to lower or retract the blade until it looks parallel to the sole of the spokeshave when sighting the cutting edge for alignment with the sole of the spokeshave from the front edge. The more the blade is visible, the deeper the cut will be. To test out the depth, use a long thin piece of wood about ½” thick, take a shaving from one side of the blade and then, using the same pressure, take a shaving using the other side of the blade. If the thickness of the shavings are similar, this means that the depth of the cutting iron is similar on both sides. If the shavings are different, adjust one side until they match.

Some spokeshaves may clog when used for the first time due to the shape of the cap iron. Follow the steps below to refine the cap iron and improve the spokeshave’s performance.

Cap Iron before and after gallery:

The first picture shows what the underside of the cap iron looked like before and after refining. When we received it the red paint was thick and rounded at the point where the cap iron meets the cutting iron. The second picture shows another comparison between what it looked like before and after it was refined.

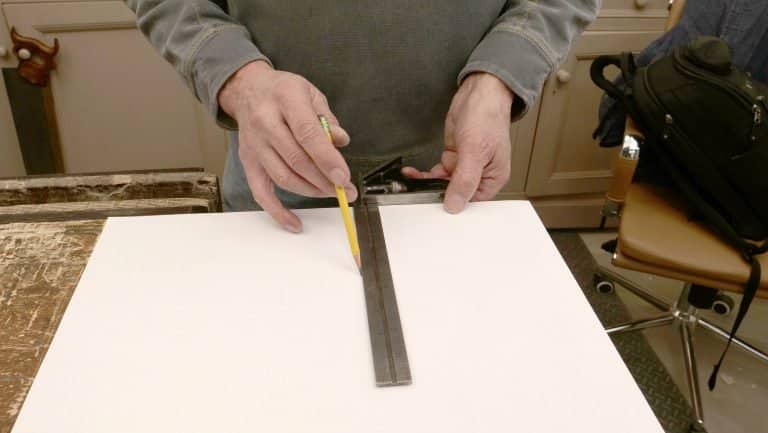

To refine this front edge of the cap iron place it on a scrap piece of wood and position it so it slightly overhangs the edge. Put a screw in the hole to keep the cap iron in place, make sure not to tighten this too much as it can fracture the cap iron. Use the file to take long strokes towards the edge of the cap iron, if it moves during filing put two side screws in place as shown. Continue filing to the edge of the cap iron until you have achieved a silver band where the paint has been removed.

Reposition the wood in the vise at an angle, use the file to create a camber on the edge of the cap iron followed by abrasive paper. Reposition the wood once more, this time so it is vertical. Draw file along the edge of the cap iron.

Take the screws out of the wood and use the diamond stones to flatten the reverse side of the cap iron. If, as in this case, the paint is thick, secure the cap iron back onto the piece of wood and use the file to continue flattening the underside of the cap iron.

Flatten the sole of the spokeshave on the diamond stones to further refine it. Consider also using the flat file if the sole seems unevenly undulated. To soften the surface and corners use abrasive paper then finish with a coat of oil.

Sharpening

Note: This guide will be focused on sharpening a bevel-down spokeshave, however it should be noted that this is not the same process for a bevel-up spokeshave.

The angle at which you present the blade to the sharpening plates is important because if it is too steep, the cutting edge will be higher than the heel of the bevel, which prevents the blade from reaching the wood to cut. Using the same tools and techniques as sharpening a chisel, you will be using the 3 different sharpening plates. Like sharpening any other blade, you want to ensure the angle of presentation is correct to allow you to create a camber on the bevel. To do this, make sure when you are sharpening the bevel on the plate to slightly lower your hand so you finish on the heel of the bevel. To create bevelled corners to each side of the cutting iron, tilt the blade slightly onto the corners. This bevels the corners which means you don’t leave harsh lines in the surface of the wood when cutting.

Tip: Some people find it difficult to hold the blade when sharpening as it is so short and can be hard to grip, you can extend this using a blade extender which can be easily made by hand. See Paul’s video on how to make a blade extender here.

Further Reading

To read more on spokeshaves, we recommend the following from Paul’s blog:

Setting The Traditional Wooden Spokeshave

Final On #151 Spokeshave Restorative Work Series- Maybe!!

How To Sharpen A Traditional Wooden Spokeshave

Grinding And Honing Spokeshave Blades

Thanks for the thorough and clear setup and sharpening tutorial.

I could use some help and advice. I’ll try to keep this short. I am creating a leg for a piece. The leg is 1 7/8 inch maple about 36 inches in length. Two sides of each leg are flat and parallel and two are curved. Think of it as a crescent, however the radius of the concave and convex sides are shallow. I have used a bandsaw two cut the legs to shape and now want to smooth the curved faces. I have attempted to use a spokeshave with no success. It stutters terribly. I have set it and sharpened as recommended. When I use it on a flat 3/4 inch edge of scrap lumber I can cut very thin even strips just as if I am using my smoothing plane. I am very aware of the grain and am taking great care to work “downhill”.

Is this the right tool for the task?

Any advice would be appreciated.

Hi Curt,

Paul suggests that because it’s 1 ⅞ wide, that’s also the width of the blade which makes it more problematic and more difficult to use. It is better to use a well sharpened card scraper.

Kind Regards,

Izzy

Thanks. That is where I ended up, as well. I am getting pretty good results, just slower than I had hoped.

Thank you for this article! I re-discovered this site in one of Paul’s blogs. My new 151 spokeshave is clogging and If course I thought it was me. It’s not a surprise that Paul already fixed the problem! It maybe worth it to mention this site in masterclass videos to get the word out a bit more. Or maybe I’m just the weirdo that forgot it.

I appreciate this. I was wondering just how to sharpen mine. Now I have been informed by the expert. Thank you.

Hi Kathleen,

Im pleased to hear you found this guide useful!

Kind Regards,

Izzy

Are there any entries on how to set up an older Stanley spokeshave that does not have the adjuster screws?

Hi Collin,

Paul says the principles are all the same. It’s actually simpler as you don’t have any adjuster screws and most often craftsmen simply used the hammer tap to deepen the cut or offset the cut with a deeper setting on one side and lighter setting on the other. No further adjustment was needed after that.

Kind regards,

Izzy

Thank you for this blog entry, though I wished that it might have continued further. After waiting over a week for the Stanley 12-951 I purchased from Home Depot to arrive having shipped from California to Maine, its thorough fettling is seeming that it will take just as long to complete, or be returned to Home Depot for a refund. It arrived in very rough shape. Stamped into the casting of the back of the body/handle just above the mouth is “No151” with the top of the first “1” having been drilled out to receive the cap iron’s retention screw. At this point, it seems that the 12-951 and the 12-151 are principally the same.

I flattened and polished the back, and sharpened the majority of the bevel to perfection, all but for one corner on the back where the manufacturer’s grinder had spent one second too long. I thought that simply not using that tiny bit of the blade at its corner could be avoided without having to shorten the blade by more than a 1/4″. Does that make sense? Or should the blade simply be replaced?

After removal of the paint and a goodly bit of iron from the backside of the cap iron, the portion that still shows paint is on the edge of the casting is near a sizeable chip where the edge is bent upwards, and I’m unsure how best to straighten it, or is this one tool that falls beyond redemption? Is the cap made of ductile cast iron? Can it be hammered into shape or is it too brittle?

The cap iron’s maximum width is about 2.34″ which includes to the (2) resting shoulders, each about 0.13″. The body’s bed opening that receives the cutting iron and cap iron is about 2.26″ wide where the two shoulders rest. This leaves less than 0.04″ for the cap iron to to rest and rock upon, but only if it can be precisely positioned. In other words, how can one determine if the cap iron’s width is too small?

Then there’s the related issue of the cap iron’s retention screw notch preventing the cap from even contacting the resting points on body/ bed. Should the cap iron’s retention screw notch be elongated to allow for the cap iron to slide more closely towards the sole?

In the photo of Paul flattening the sole of the spokeshave on the diamond stones, the bed looks like all of the paint is still gobbed on. Since the blade rests against this part of the body, something akin to the frog on the plane, should this surface be cleaned and flattened? Should the entirety of the blade bed be filed flat or just nearest the mouth at the sole?

I would have included photos with this posting; however, saw no means of doing so.

Thank you for any reply.

Kind regards,

Kelly

Hi Kelly,

Thank you for your comment.

Paul says:

The best thing to do is to put the cap iron in and see how it works. If it’s working you don’t need to do anything, if it isn’t working you have to keep fettling it until it does work. Alternatively just send it back and ask for a replacement or your money back.

Kind Regards,

Izzy

Hi Izzy,

Thank you very much for your kind reply and for relaying Paul’s thought’s. I will be asking for a replacement because the cap of the Stanley 12-951 received was so badly chipped and bent, even after filing it’s back and removing a full 1/8″ of material between the retention screw and the leading edge, the nose of the cap still shows clear signs of the defects and chips quickly clog up the works with anything other than clear long grain cuts.

I still have one question regarding the bed of the spokeshave. In Paul’s illustration (https://paulsellers.com/wp-content/uploads/2014/07/DSC_00013.jpg) of the section through the spokeshave, I noted that the line of the bevel-side of the cutting iron and the upward face of the bed, are co-planar and both extend to the the flattened sole. This is conceptually similar to my jack and smoothing planes; however, on the subject spokeshave, there is a decided 10° deflection caused by the manufacturer’s ground surface at the mouth of the sole. Does this matter?

Also, does it matter if when held to the light, we see the cap iron not fully contacting the back (upward facing) side of the cutting iron? Similarly, does it matter if light can be seen between the frog and the bevel-side of the cutting iron?

Hi Kelly,

Paul says:

It works perfectly well.

Kind Regards,

Izzy

Thanks for this great site with great information and tips. I have a question about the blade and the hole for the regulation screw.

I have a Kunz 51A Spokeshave and the problem that I want to resolve is the wideness of the hole of regulation screw respect the height of the the bolt that press up and down the blade. Is there a way to solve this problem?

Thanks in advance.

Sebastiano

Hi,

I passed your question on to Paul and he said:

Throw it away, in my opinion they’re the worst tool makers in the whole of Europe.

Kind Regards,

Izzy

This guide is excellent! I have a new Stanley 151 and was experiencing clogging after every couple of strokes. After following Paul’s steps, the spokeshave works like a charm and I was able to easily finish the arched rails for the hanging wall shelf project.