The Square Guide

…as 90°. Types of Squares The two most commonly used types of square are the combination square and the try (tri) square. The main difference is that the combination square…

…as 90°. Types of Squares The two most commonly used types of square are the combination square and the try (tri) square. The main difference is that the combination square…

…Further Reading To read more on squares, we recommend the following from Paul’s blog: Questions Answered- Box- Storing a Combination Square Checking Your Squares Squareness Fixing an Old Tri Square…

…the combination square, we recommend the following from Paul’s blog: On Woodworking Squares and Working Wood My Minimalist Tool List- The Square Buying Good Tools Cheap 2- The Combination Square…

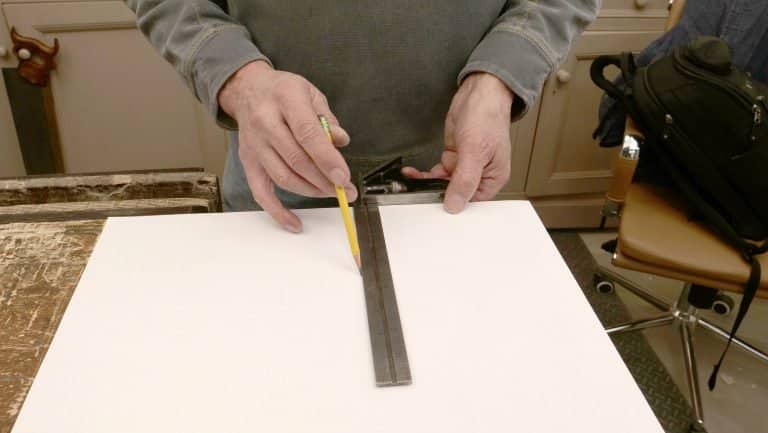

Paul Sellers recommends a 12″ (300mm) combination square as this should be suitable for almost all woodworking projects. He finds the try squares don’t remain accurately square as with the…

…somewhere not too close to the ends. With the square still in place, bring in the tenon piece right up against the square to keep it perpendicular, and make a…

…Without moving your square, make a very light knife nick on the corner Use that knife nick to align the square and make a second knife nick in the following…

…from the previous face, slide the square up and create a knifewall. 5. On the final face, flip the square and turn the wood. Register the square against your face-…

…Begin by using your square to make the first knifewall right in between the gauge lines on the first pencil line. Be sure to place the square so that the…

…chisel hammer and a square to ensure these are all lined up. Mark 1 ⅛ “ (29mm) from the end, use the square to square this across all 4 aprons….

…compressibility that pine would, for example. Paul checked how square the join was and concluded it was ‘dead square’: Paul identified a gap on the bottom of one of the…