How to Make a Sharpening Stones Holder

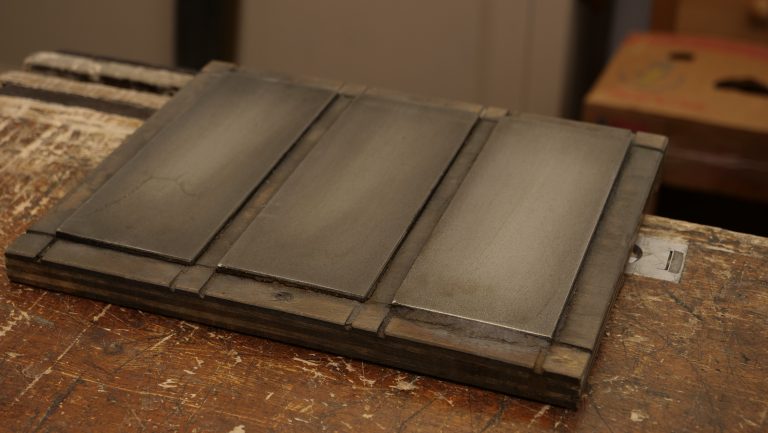

In this guide, Paul shows you how to make a sharpening stones holder which can be clamped in the vise for ease of use. For this, you will need: Plywood…

In this guide, Paul shows you how to make a sharpening stones holder which can be clamped in the vise for ease of use. For this, you will need: Plywood…

…the stone’s surface will become glazed and thereby unusable for sharpening. You can buy man-made double-sided oilstones with both fine and coarse grit in a single stone. Oilstones can be…

…Stones, we recommend the following from Paul’s Blog: Sharpening Stones– Watch out for the Bumps Questions on Sharpening Stones Questions on Diamond Sharpening Methods, Stones and Plates Filing/ Honing Guide…

Note: Be careful when sharpening as the tools will become very sharp, always face the blade away from you when sharpening. Setting Up If your spokeshave is secondhand, check the…

…edge to create a border, put one of your diamonds stones on this border line… Buying Diamond Stones18 April 2019 When buying diamond stones, Paul suggests getting a coarse stone…

…Sharpening a Knife Sharpening a Gouge Sharpening a Brace Bit Sharpening a Card Scraper Sharpening a Plough Plane Sharpening a #80 Scraper Sharpening a Router Plane Sharpening a Chisel Our…

…use abrasive paper as a short term substitute until you decide to invest in the diamond stones. Diamond Stones To set up and sharpen your chisel using diamond stones, you…

…the sharpening stones. If the newly abraded surface is parallel to the cutting edge, the edge is in line. Use even pressure on each level of coarseness until the whole…

…First Crosscut Saw- Part 1 Sharpening Your First Crosscut Saw- Part 2 Radical Changes For Saw Sharpening Video Magnetised Saw Sharpening Holder Coping And The Cost Of Coping Saws And…

Note: Be careful when sharpening as the tools will become very sharp, always face the blade away from you when sharpening. To jump straight to ‘Sharpening’, click here. Setting up…