Sharpening a Card Scraper

Sharpening

Draw file along the 2 long edges by pushing the file away from you, small steel spirals should appear from the edges as a result of the filing.

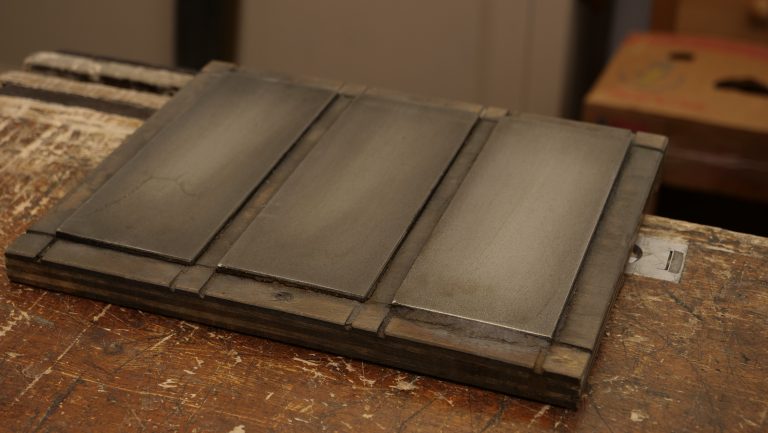

Place each long edge against the diamond sharpening plate keeping it vertically aligned and push and pull it 10 times making your way through all the 3 grades from coarse to finer.

Next, to remove any unwanted burr, place the large face against the super-fine plate and rub back and forth. Make sure your fingers are evenly spread to cover as much of the surface adjacent to the newly formed edges as possible to evenly distribute the pressure. Repeat this to all four corner surfaces.

Use the burnisher to develop the edge, which further consolidates the steel. This strengthens the inner steel and reinforces the thin edge so it is less prone to crumble under the pressures of scraping. You can do this in the vise or by holding it freehand but make sure you have something to protect your inner palm and the sides of your hand from the scraper blade and the burnisher when doing this.

Lubricate the burnisher with oil, lay the card flat on the surface then run the burnisher along the face 30 times keeping it flat, this is referred to as ‘flat face consolidation’.

Next, consolidate the long edge, with the scraper standing tall on the workbench, use a burnisher square on and press hard while moving the burnisher up and down the long edge, this is known as ‘square edge consolidation’. For the final few strokes, increase the angle by a few degrees so it is no longer square on, this will gradually turn the corner to give the scraper a turned edge. Repeat this to each of the other three corners.

Further Reading

To read more on the scraper, we recommend the following from Paul’s blog:

Using the Card Scraper- A Good Heel Beats Two Thumbs

Hi,

As I have to buy a set of Veritas card scrapers nearby in Belgium, the use of a burnisher seems to be necessary for sharpening the scrapers. What kind of burnisher is recommended by Paul and where can I buy it?

Kind regards

Marc De Mits

Hi Marc,

I asked your question to Paul and below is his answer:

We don’t really recommend a specific manufacturer because the burnisher itself is such a basic standard tool that there is no one better burnisher over another. You can use any hard steel round, square, triangular or oval to burnish a scraper edge.

Kind Regards,

Izzy

Dear Izzy,

Has Paul ever shown or written how he sharpens the inside curve of a goose neck card scraper? Perhaps a 1/2 round file or…?

Thank You! Hope I’m not asking too many questions.

Warmest Regards,

stephen

Hi,

No he’s never done one because he finds them useless. However the procedure is the same as a straight one. Usually Paul finds it best just to make a radius suited to the task in hand in the same way he does for making a rounded card scraper.

Izzy

A little off topic but coming from a different discipline I use glass offcuts (cullet) for scraping.

As I had 3 or 4 tons of cullet under the bench in strips up to 2″ wide to use .

I cut a slight curve along one edge of the glass about 18″ long (3mm or 4mm thick usually) to give it a very slight crown, then a few cuts here and there to let me snap off pieces as required.

You only get 1 good cutting edge, the side where the glass cutter worked being too rough.

Once dull they went back under the bench with the rest of the waste.

A disposable hardened saw can have a second life as scrapers too.

Does a video counterpart exist for this guide? I haven’t found one in my searches.

Thank you.

Hi Austin,

This guide just contains photos, if you want to see a video of this there is one on Woodworking Masterclasses which I have linked below:

https://woodworkingmasterclasses.com/videos/card-scraper-sharpening/

Kind Regards,

Izzy